Mastering Bulk Material Handling for the Electronics and 3D Printing Industries

In the fast-paced world of industrial operations, particularly within the electronics and 3D printing sectors, the importance of effective bulk material handling cannot be overstated. This intricate process encompasses the various methods and technologies used to transport, manage, and store bulk quantities of materials efficiently. Proper management not only enhances productivity but also significantly reduces operational costs and environmental impact.

Understanding Bulk Material Handling

At its core, bulk material handling refers to the movement and processing of materials in large quantities, as opposed to smaller, more manageable amounts. This is particularly relevant when dealing with raw materials used in the electronics and 3D printing industries, where efficiency and precision are paramount.

Key Components of Bulk Material Handling

The effective management of bulk materials revolves around several key components that ensure smooth operation:

- Conveying Systems: This includes the various mechanical systems used to transport materials from one point to another, such as conveyors, elevators, and pneumatic systems.

- Storage Solutions: Effective storage systems must be employed to handle large volumes of materials, including silos, bins, and hoppers.

- Loading and Unloading Equipment: Equipment such as forklifts, cranes, and bulk material handlers facilitate the efficient transfer of materials to and from storage and production areas.

- Software Systems: Advanced software solutions for inventory management and logistics are critical in tracking the flow of materials, aiding in the planning and forecasting processes.

Why is Bulk Material Handling Crucial for Electronics and 3D Printing?

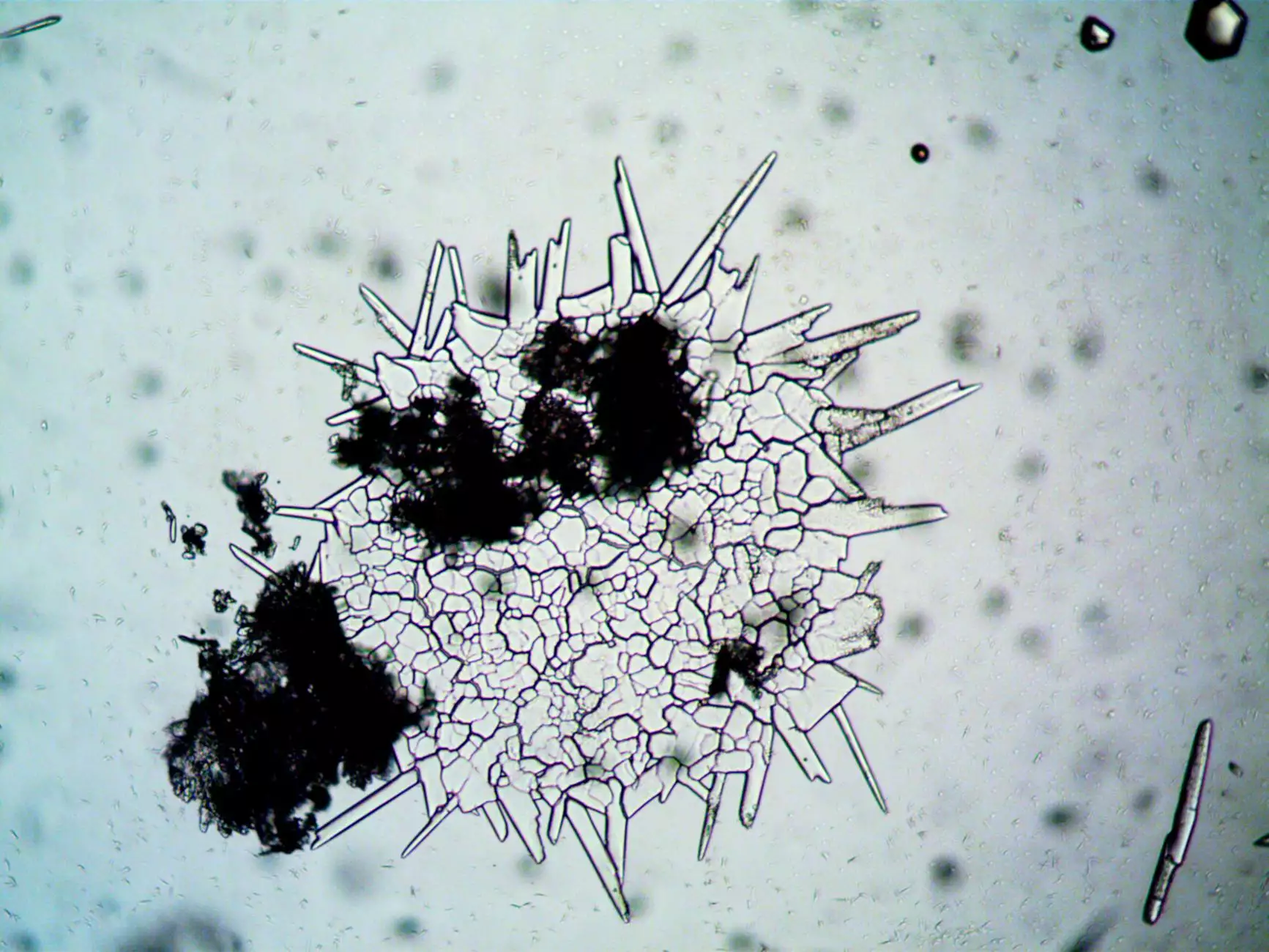

In the electronics industry, precision is essential. The materials used, including metals, semiconductors, and polymers, must be handled with care to avoid contamination or damage. In the 3D printing sector, the digital nature of the manufacturing process relies heavily on the effective handling of materials like filaments, powders, and resins to ensure successful printing outcomes.

Enhancing Operational Efficiency

By leveraging advanced bulk material handling methods, companies can streamline their operations. This includes:

- Reducing material waste through precise handling techniques.

- Minimizing downtime with faster loading, unloading, and transfer processes.

- Improving safety measures for workers by utilizing automated systems.

Meeting Industry Standards

Both industries are subject to rigorous regulations and standards. Effective bulk material handling practices not only help businesses comply with these standards but also enhance their reputation by ensuring high-quality output.

Innovative Technologies in Bulk Material Handling

The advent of technology has transformed bulk material handling practices. Here's a look at some of the cutting-edge solutions redefining the landscape:

Automated Systems

Automation is revolutionizing how materials are handled. Automated guided vehicles (AGVs), robotic arms, and automatic storage and retrieval systems (AS/RS) are being integrated into production lines to reduce labor costs and increase efficiency.

Data-Driven Management

With the rise of the Internet of Things (IoT), data analytics is making significant strides in material handling. Real-time data collection allows companies to monitor inventory levels, optimize routes for material transport, and predict maintenance needs, seamlessly improving operational workflows.

Sustainability Initiatives

As companies strive to lessen their environmental footprint, bulk material handling systems are being designed with sustainability in mind. This includes using energy-efficient machinery, reducing waste through precise material management, and incorporating recyclable materials into production processes.

Implementing Effective Bulk Material Handling Strategies

To optimize bulk material handling operations, businesses should consider the following strategies:

1. Assess Current Operations

Conduct a thorough analysis of current material handling processes. Identify bottlenecks and inefficiencies to understand where improvements can be made.

2. Invest in Quality Equipment

Select high-quality equipment that meets the specific needs of your operations. Investing in durable and efficient machinery can yield long-term savings and reliability.

3. Train Staff Effectively

Ensure that all employees are trained in the proper handling and operation of machinery. Safety training is just as critical to avoid accidents and maintain a productive workplace.

4. Monitor and Adjust

Once new systems and practices are in place, continuously monitor their effectiveness. Be open to making adjustments based on performance data and shifting operational needs.

Challenges in Bulk Material Handling

Despite the advances in technology, the bulk material handling process is not without its challenges:

1. Material Variability

Selecting proper handling techniques can be complex due to differences in material properties. Understanding how each material behaves during handling is essential for preventing damage and optimizing workflow.

2. Space Constraints

Many operations face space limitations that hinder effective bulk material handling. Creative storage solutions and optimized layouts can help mitigate these issues.

3. Labor Shortages

Finding skilled labor for operating advanced material handling systems can be difficult, leading many companies to consider automation as a solution.

The Future of Bulk Material Handling

As we move forward, the evolution of bulk material handling will be guided by the need for greater efficiency, safety, and sustainability. Companies must remain adaptable, embracing new technologies and methodologies to stay ahead in a competitive market.

Emphasizing Continuous Improvement

The most successful companies in bulk material handling will prioritize continuous improvement. By regularly evaluating and refining their processes, they can enhance productivity and ensure they remain at the forefront of their industries.

Conclusion

Effective bulk material handling is a cornerstone of success in the electronics and 3D printing industries. By understanding the importance of this process and implementing strong handling strategies, businesses like Polygon Machinery can optimize their operations, maximize their resources, and ultimately drive greater profitability and sustainability in their practices.